Factory Automation

Bearing Defect Detection

During production or assembly of a bearing, there may be defects like depressions, scratches, indentations, missing balls and size deviations on the surface of inner and outer races and the end face of the seal ring as well as character recognition problems on the bearing surface. These defects may seriously compromise usability of the bearing. Traditional manual detection is flexible, but humans tire easily or are susceptible to individual subjective factors. The machine vision detection system can work continuously for a long time based on consistent detection criteria and therefore provides highly precise results.

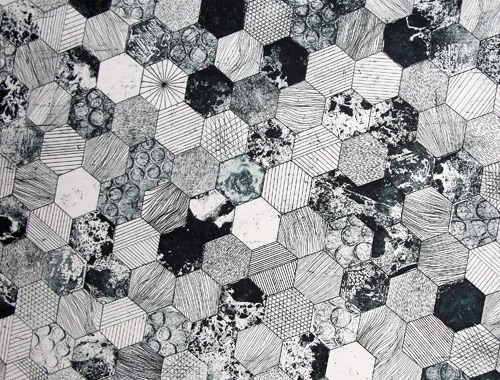

Textile Defect Detection

Traditional textile quality testing mainly rely on artificial detection methods, vulnerable to the subjective experience of the workers, judgment and attention. Using machine vision detection method, can greatly improve the accuracy and reliability of detection results, increasing the overall efficiency of the production line.

| About us | Contact us | Data Privacy Policy